A modular home (ⓒkoma-modular)

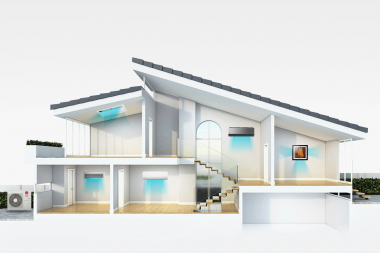

Air conditioning systems can be very complex and include various components such as compressors, fans, condensers and evaporators. These systems also come in many different sized with a wide range of configurations. One compressor can feed one indoor unit or many indoor units and multiple compressors can feed multiple indoor units depending on the application of the system. Modular design not only makes installation of these systems much easier, but it also makes the maintenance and repair process much simpler and allows system capacity to be configured to improve overall system efficiency. The precise control allowed by modular air conditioning systems simultaneously increases efficiency while providing better comfort to users.

LG G5 Modular mobile phone concept

How it Works

When an air conditioning system is installed, the system designer must first establish the scale and capacity the system will require. The project manager will then order a system to the scale required and begin installation. Modular design makes this process easier by making it possible to select the required parts such as compressor units and indoor units, and then plug the components into the desired configuration. Similar to changing out a position player in football, when a component breaks down or wears out, that component can easily be replaced with a new component that can be plugged in its place. In large systems, there is likely to be a large number of compressor units and indoor units located throughout the building or facility. Since the system does not need to run a maximum capacity at all times, fewer compressors can run during low-peak times to conserve energy and reduce wear on system components.

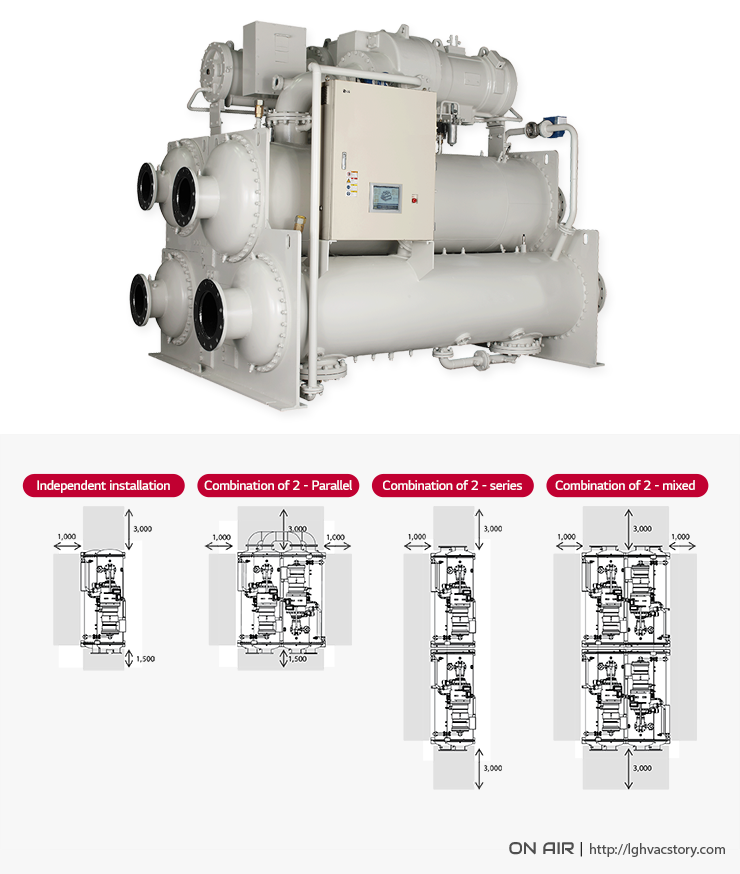

LG modular HVAC components

LG Modulation

LG Air Solution, of course, offers modular design in the new Multi V 5 solution and also in their centrifugal chiller series. Modular design in large scale chiller systems has a great impact due to the size of the systems and number of components in the systems themselves. As inverter systems can sometimes have issues with high-frequency noise emission that can cause damage to glass or sensitive products, a modular chiller is ideal for use in proximity to product production lines. LG installed 4 2000RT centrifugal chiller units at a Hyundai Motors production plant and the plant eliminated issues they were having due to high-frequency vibrations, which helped in Hyundai deciding to convert to LG centrifugal chillers.

Modular designs are changing how we design products and are providing a number of advantages over conventional system designs. LG is also using their modular designs to offer smarter and more efficient types of air conditioning systems. As modulation is implemented in more and more fields and products, we are sure to continue to see modular systems more commonly in our daily lives. You may even be using one now!