As industries look to make their offerings faster and more accurate, many companies struggle to accomplish both. Markets are demanding faster technological advancement and customers require more advanced solutions. With this continue escalation of demands, manufacturers are focusing on optimizing their processes and streamlining their facilities. Administrators at production facilities and R&D centers must find ways to improve efficiency and maintenance processes while ensuring the reliability of each system. They must also ensure a safe and comfortable environment across a diverse set of spaces within their facilities with an efficient and convenient HVAC solution. This is where LG Oil-Free Inverter Magnetic Bearing Chillers are helping facility administrators attain their goals with efficiency, convenience, reliability and flexibility.

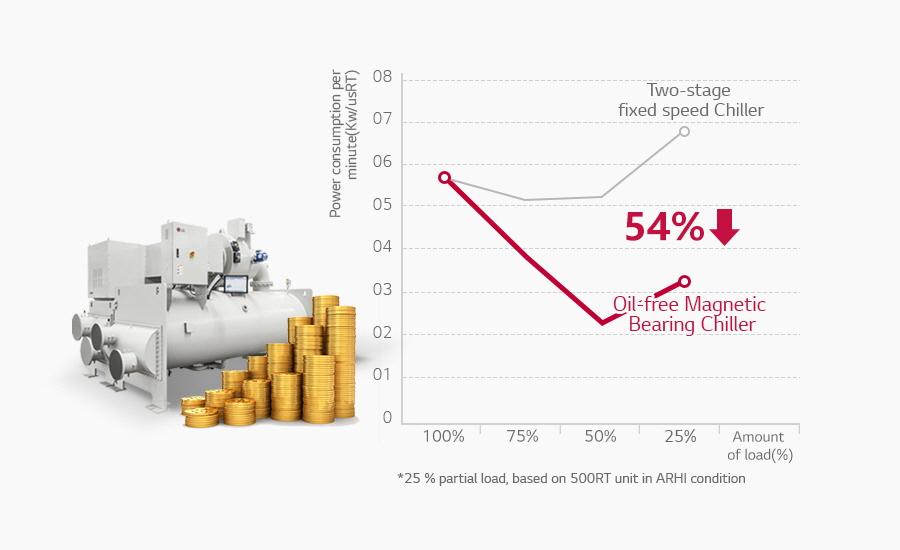

Reduced power consumption is one of the many benefits afforded by oil-free chillers

Reduced power consumption is one of the many benefits afforded by oil-free chillers

Performance and Efficiency by the Numbers

The LG Oil-Free Inverter Magnetic Bearing Chiller is equipped with LG’s own inverter compressor that is capable of achieving world-class efficiency and delivering a Coefficient of Performance (COP) of 7.0. LG’s inverter compressor boasts an Integral Part Load Value (IPLV) of 12.0 while lowering operation costs by as much as 36% compared to conventional chillers with the elimination of an oil management system. In addition, the LG Oil-Free Inverter Magnetic Bearing Centrifugal Chiller implements a high-speed direct connection with the inverter compressor to reduce noise emission to a mere 73dB.

A smaller footprint allows for more efficient use of space and easier installation

A smaller footprint allows for more efficient use of space and easier installation

The Convenience Needed to Stay Ahead

The Oil-Free Inverter Magnetic Bearing Chiller also revolutionizes the maintenance process with a black box capable of instantly documenting issues with performance and allows for immediate and easy assessment so action can be taken to resolve any problems. Without the need for an oil management system, this chiller solution has a smaller physical footprint to improve available space and make installation easier to manage. Even with this smaller footprint, the Oil-Free Inverter Magnetic Bearing Chiller comes in a wide range of capacities with 200RT-1,100RT and 200RT to 2,200RT for single compressor packages and 400RT to 2,200RT for dual compressors. These varying capacities make this chiller solution ideal for many different applications, such as ice storage cooling to large-scale industrial cooling.

Integration through LG BECON control enhances efficiency and performance

Integration through LG BECON control enhances efficiency and performance

Power through Flexibility

The flexibility and comprehensive control provided by the Oil-Free Inverter Magnetic Bearing Chiller from LG is also giving system administrators the power to manage their facilities more effectively. The chiller system can be integrated into LG’s Building Energy Control (BECON) solution for 24-hour consolidated administration, including temperature control and energy cycle monitoring. This allows the chiller to communicate with other important systems within the facility for clearly improved efficiency and more effective operation.

With increasing demands and a higher level of competition in the markets today, facilities can afford to fall behind. A streamlined and more effective facility makes for a more potent and competitive business. Any commercial production or R&D facility can use every advantage available to stay ahead of competitors and LG is providing the perfect solution in the Oil-Free Inverter Magnetic Bearing Chiller. This is the solution with the efficiency, convenience, flexibility and reliability any business can trust to succeed.