When the engine of a car breaks down, there are many steps you can take to repair or maintain the car to keep it running. But sometimes, your only option is to start looking for a new car. This decision isn’t an easy one and it can cost you a fair amount of money. However, having a new car will improve your day to day operations and can ultimately save you the frustration of dealing with a deteriorating vehicle while affording you advantages, including more comfort, better efficiency and peace of mind.

While replacing an HVAC chiller system is a much larger investment than purchasing a new car, the process of deciding whether you need a new one can bring about some of the same concerns and considerations. This process is not an easy one, but we would like to offer some advice to help you along the way. In the first part of this 2 part series, we will cover some of the signs that it might be time to replace your chiller system. We will then wrap up in part 2 by providing information to help determine which chiller is right for your facility. Now, let’s begins with indications of a chiller system that might need more than just an overhaul.

As Chiller Technology Advances, Your Current Chiller may be Behind the Times

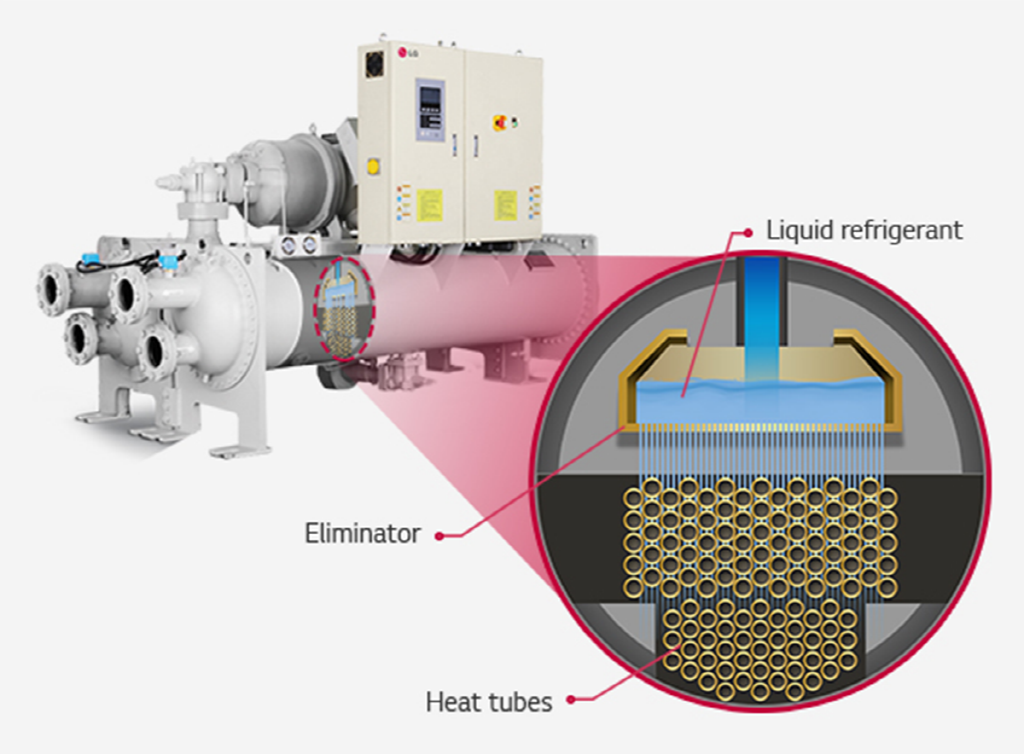

Chillers have evolved over the past 20 years to include many innovative and efficiency components

Chillers have evolved over the past 20 years to include many innovative and efficiency components

Over the past 20 years, HVAC technology has come a long way ad many of the advancements in the field have made older chiller technology obsolete. Today’s chillers may only require a much smaller percentage of the energy required by an older system. The efficiency of a new chiller will help in offsetting the investment of a new chiller over time. If your chiller has been operating at heavy loads for close to 20 years, it may be experiencing significantly lower efficiency.

The Reliability of an Older Chiller will Continue to Decline

As a chiller system ages, certain factors begin to diminish overall performance. Components wear down dramatically over time and scale can accumulate to impact the durability and effectiveness of your chiller. System outages can also become more frequent as durability declines. Although regular maintenance can curb some of these effects, performance will ultimately suffer.

Changes in Operation Load

As your facility changes and grows, so will the requirements of your chiller system

As your facility changes and grows, so will the requirements of your chiller system

Over the life of a chiller, operational, structural and occupancy changes will occur in the facility where it is installed. Operation hours may have increased or changed and there may have been renovations or upgrades to the facility itself. There may also be more employees working in the space, which could require heavier loads on the chiller. These types of changes affect the effectiveness of the chiller system and the system installed may not be right for the current facility.

Improved Operation and Control Makes Your Chiller System More Convenient and Efficient

Modern control capabilities improve system efficiency

Modern control capabilities improve system efficiency

Poor performance of a chiller or even outages can affect more than just the comfort of the occupants, but also hinder the operations of a facility itself. Ease of use is an important factor to consider as that will impact convenience and performance. Modern control functionality will make the system easier to manage and improve efficiency in a more complex, modern facility. Operability can be a major factor to consider when assessing the need for a new chiller.

Completing a thorough assessment of your chiller’s performance and cost analysis considering the criteria above will be an important factor in the decision to replace your chiller. If your chiller system is over 20 years old, you have probably noticed many of these issues and it may be time to consider investing in a new chiller. In the end, the cost and energy savings of installing a new chiller will ultimately outweigh the initial investment. The next step is to figure out which chiller is most suitable for your facility. Be sure to check back in for part 2 of this series to learn more about the chiller selection process.