In the first part of this series we covered the importance of assessing your HVAC chiller’s performance for signs that it might need to be replaced. If you’ve determined it’s time to upgrade your chiller system, the next step is deciding the right chiller for your facility. Factors that should be considered in this process include the size of the facility, the use of the facility as well as the climate where the facility is located and available energy resources. The decision to invest in a new chiller is not one to be taken lightly but we hope we can make the process easier and set you in the right direction.

Size Does Matter

The size of your facility will certainly factor into the type of HVAC chiller system will suit you best. For a large-scale facility such as a factory or a commercial space like a shopping mall, absorption and centrifugal chillers are typically the most effective options. More efficient water-cooled centrifugal chillers can also be coupled with an absorption chiller to utilize waste heat and further improve overall system efficiency. Smaller air-cooled chillers can also be used to handle loads for areas that are critical to operations such as system control rooms and data centers.

Mid-sized buildings such as smaller-scale hospitals or offices are better suited for implementing screw chillers. These

could be air or water-cooled chillers depending on the installation environment. If there is an inexpensive heat source available, an absorption chiller may also be ideal.

In smaller buildings like retail spaces, air-cooled scroll chillers are a more suitable choice. Scroll chillers are typically smaller and can have a modular design, making installation in smaller facilities more convenient and flexible.

Environment as a Deciding Factor

Centrifugal Chillers Offer High Efficiency for High Operation Loads

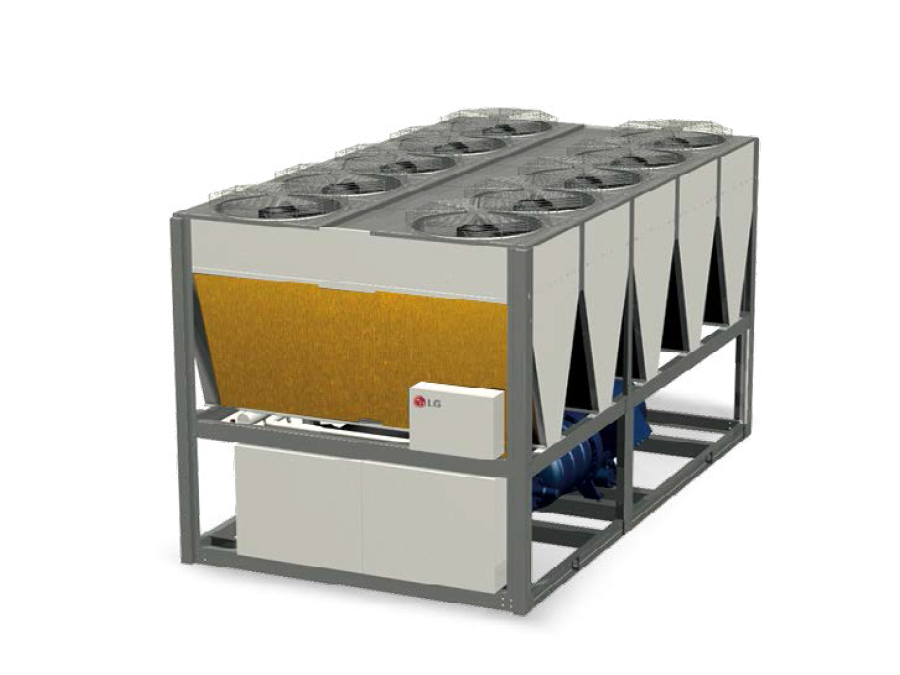

Water-Cooled Centrifugal Chiller

Water-Cooled Centrifugal Chiller

While building size is important in determining which chiller type is right for your facility, other environmental factors come into play. Water-cooled centrifugal chillers require a consistent source of clean, treated water since they use the water evaporation process to dissipate heat. Water towers are typically needed to as reservoir for this water and space will be required on the facility premises to house a tower. Centrifugal chillers are also massive machines that must be housed inside and take up a lot of space on site. Although these chillers usually boast higher levels of efficiency and can handle larger operation loads, they also require a greater initial investment as well. In addition, centrifugal chiller offer an oil-free option that not only improves efficiency even further, but also reduces wear on components by eliminating friction on key moving parts to prolong the life of the equipment and reduce the need for maintenance. You can see a video of how LG’s oil free centrifugal chiller works by clicking the link here.

Absorption Chillers Provide a Great Way to Offset Peak Energy Costs

Absorption Chiller

Absorption Chiller

Absorption chillers offer the unique capability of utilizing waste heat for operation. If you have access to a source of waste heat such as runoff from a manufacturing or water treatment facility, an absorption chiller might be an ideal choice to offset peak energy costs. Absorption chillers are also typically implemented alongside a mechanical chiller system to help improve overall system efficiency.

Screw Chillers Provide an Efficient Solution for Medium-Sized Buildings

Air-Cooled Screw Chiller

Air-Cooled Screw Chiller

Screw chillers can be either air or water-cooled, and while the water-cooled option is more efficient, if you have a medium-sized building but lack a steady source of clean water, the air-cooled option might be the right fit. Water-cooled screw chiller also can be implemented to use geothermal heat pump applications or even ice storage for even better efficiency returns. Air-cooled screw chiller must be installed outdoors and will require space on the roof or nearby location on site.

Scroll Chillers Offer a Flexible Modular Design

Air-Cooled Scroll Chiller

Air-Cooled Scroll Chiller

Scroll chillers are typically installed outdoors as they are mostly implemented as air-cooled chillers. However, as discussed above, they are a smaller form factor and can have a modular design, which offers easier scalability and flexibility in system design for smaller buildings. Scroll chillers also have the ability to be applied as water-cooled chillers with geothermal applications if the environment where they are to be installed provides the appropriate energy source. Additionally, air-cooled scroll chillers can be implemented with ice storage to help manage costs of peak energy and improve system efficiency.

The decision to invest in a new chiller is nuanced and entails considering a number of important factors. We hope we have provided you with a helpful starting point for assessing the performance of your chiller and deciding which chiller is right for your facility. For a thorough assessment of your chiller system, feel free to contact us. Your industrial chiller system is an integral part of your facility’s operation, so we’ll do everything we can to put your mind at ease and provide the best system available.