LG’s Absorption Chillers Expand the Possibilities of Recycling

Everyone knows the virtues of recycling. From a young age, we are taught how every little bit that we do helps the planet. We’re told that every bottle we return, every paper we re-use plays a small part in making the world a better place. These days it seems like almost anything can be recycled, but our focus on physical recycling causes many to neglect important breakthroughs that take recycling to the next level.

The advanced absorption chillers pioneered by LG Electronics are an excellent example of how recent innovations are opening up new frontiers in recycling. By repurposing heat and energy, these devices have the potential to offer profound benefits to both users (in the form of lower electricity bills) and the environment (by decreasing power consumption). LG’s absorption chillers offer the best solution to the dilemma presented by increased demand for energy at a time when growing environmental consciousness is causing many to look for ways to scale down consumption.

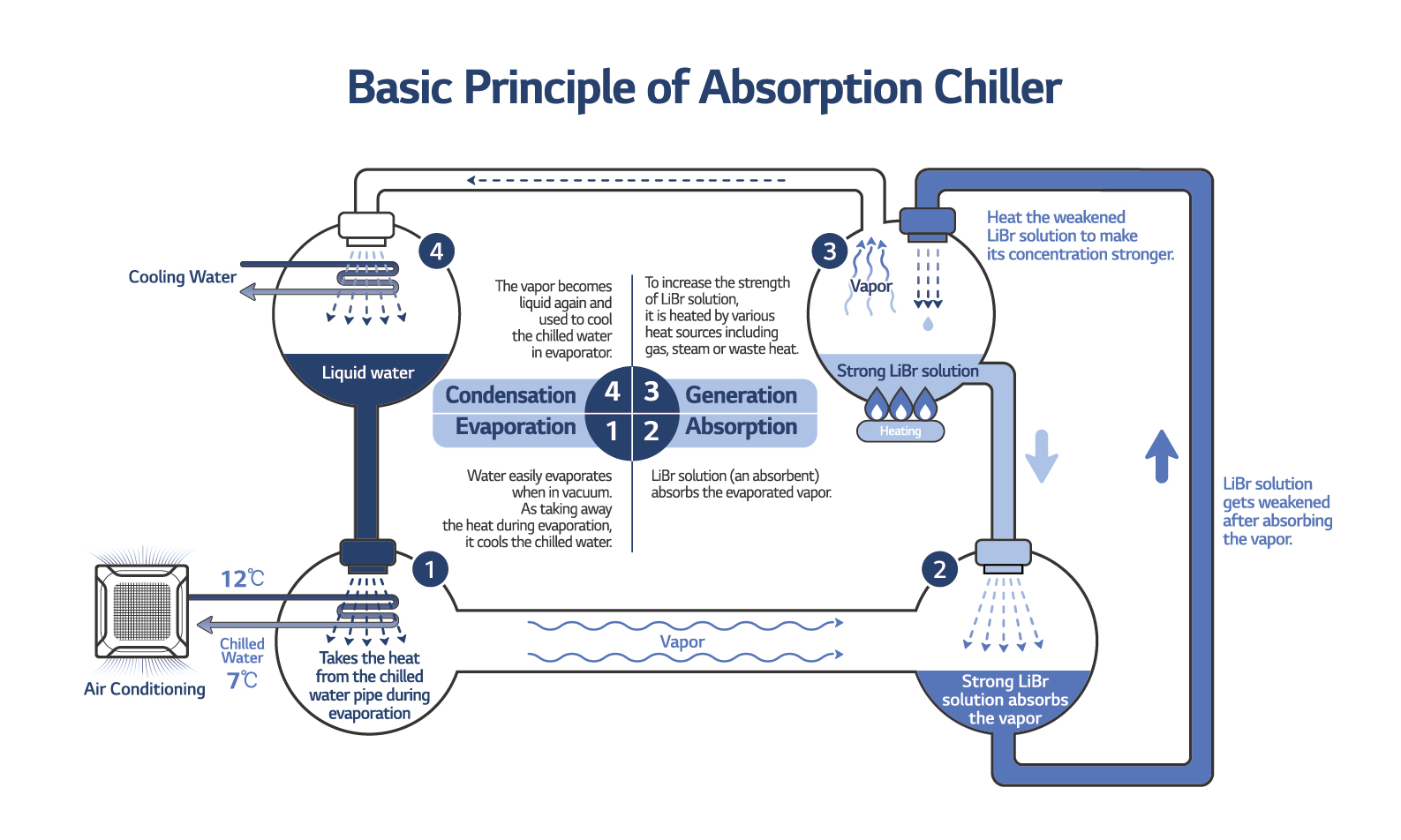

Though all of this may sound too good to be true, absorption chillers actually operate on a very straightforward principle. Anyone familiar with the water cycle will understand the basic tenets, while those with a background in AC solutions will see fundamental similarities to vapor compression chillers. This is in part because they depend on both the condensation and evaporation of the refrigerant within the system.

While electric-driven chillers rely primarily on mechanical energy, absorption chillers instead implement an advanced thermo-chemical process. This process uses LiBr (Lithium Bromide) to absorb the vapor that is formed after liquid water evaporates. LiBr is an advanced chemical compound combining bromine extracted from salt water and lithium extracted from lithium ore which forms crystalline hydrates. The absorption liquid is then created by dissolving LiBr – which has salt-like chemical properties – in water. This LiBr solution is heated and exposed to cool vapor to recreate liquid water. Operating much like the water cycle in the natural world, absorption chillers are a testament to how advanced technology can be used to reduce our environmental impact. Its incredible efficiency is made possible because absorption chillers utilize a wide range of energy sources, such as hot water, exhaust gas, or LNG. They also give users the option to use not just one heat source, but multiple heat sources.

By leveraging these multiple heat sources, absorption chillers can be combined with a co-generator – also known as CHP – to harness heat generated during electricity production to provide heating and hot water. This method of generating electricity, heat, and cooling energy by combining a CHP with the absorption chiller is called CCHP (Combined Cooling, Heating, and Power) or Trigeneration. This wide range of applications gives CCHP the ability to fill a variety of roles.

For example, CCHPs convert CHP waste heat into cooling energy, making them particularity effective in power plants as the average power plant loses more than half of the heat it generates producing electricity. Instead of letting this energy go to waste, CCHPs repurpose the heat to deliver even higher energy savings to buildings which require consistent cooling as part of their climate control regimen.

For example, CCHPs convert CHP waste heat into cooling energy, making them particularity effective in power plants as the average power plant loses more than half of the heat it generates producing electricity. Instead of letting this energy go to waste, CCHPs repurpose the heat to deliver even higher energy savings to buildings which require consistent cooling as part of their climate control regimen.

The LG Hybrid Absorption Chiller uses heat sources such as steam, hot water and exhaust gas to increase the overall energy efficiency of the CCHP system. In addition, it comes equipped with emergency backup direct gas heating that keeps the solution running in the event that CHP operation is interrupted. Ideal for users looking to reduce electric consumption via renewable energy sources, the Hybrid Absorption Chiller can even be powered by solar cells on sunny days and direct gas firing when weather turns cloudy. It is perfectly designed to provide a variety of efficient and stable cooling options.

To allow for maximum flexibility, LG gave each Absorption Chiller the ability to be easily customized according to its specified role. Solution design varies based on heat source and generator range, meaning there is a perfect chiller for every situation. This allows LG Absorption Chillers to support a wide range of temperatures – from 95 to 72 degrees Celsius – for hot water.

An optimal design that is tailored to individual generator specifications significantly raises the overall efficiency of the CCHP system. LG Absorption Chillers offer the world’s highest level of efficiency, with a coefficient of performance (COP) of 0.81 based on hot water temperature of 95°C. This incredible energy efficiency is made possible by LG’s unique high-efficiency heat transfer tube, plate-type heat exchanger, and exhaust gas fin tube.

By applying the latest engineering breakthroughs to LG’s already advanced systems, LG Absorption Chillers are able to meet the most pressing consumer needs while reducing power consumption and increasing eco-friendliness. Recycling is typically imagined as an active pursuit, something that requires participants to make sacrifices in order to reduce consumption, decrease their ecological footprint or both. Now, LG is changing this paradigm by allowing for energy and heat to be reused in a manner that requires no sacrifices on the part of the user. This represents a fundamental shift in how we think about recycling, illustrating the way forward at a time when environmental concerns vie with practical realities to determine how we design the buildings that millions of people rely on every day.