At the LG Air Solution R&D Lab, they are continuously developing the newest in HVAC technologies that are revolutionizing the HVAC market. In order to continue to achieve this, LG Air Solution has teams of engineers and researchers committed to product R&D that keeps LG Air Solution technology on the cutting edge. We had the opportunity to visit the LG Air Solution R&D Lab and experience type of extensive research that goes into the development of LG’s innovative HVAC solutions.

Environment Chamber

Sensors measuring heat, humidity and air flow

We first visited the Environment Chamber where researchers test temperature, speed, humidity and air flow to measure indoor environments and ensure that LG air conditioners operate at maximum efficiency throughout the entirety of a space. The chamber is filled with sensors that extend from the ceiling to the floor and from wall to wall. These sensors read conditions at every point within the space and this data is analyzed to detect how evenly air is being dispersed throughout the chamber. Researchers in the Environment Chamber are also developing methods to disperse air flow throughout the room without blowing air directly on people in the room in order to maximize customer comfort.

Sound & Vibration Chamber

Noise emission is tested in the Sound and Vibration Chamber.

We next entered the Sound & Vibration Chamber where testing is done to locate the location and intensity of sound from air conditioning units in order to reduce sound emissions. Upon entering the chamber, it truly feels like you have lost your hearing. This complete silence ensures that the test results are as accurate as possible. Researchers use special cameras that actually give them the ability to precisely measure the source and intensity of sound visually. This sound emissions testing is vital in reducing noise pollution and creating a more comfortable environment.

Temperature & Humidity Chamber

Outdoor environments can be replicated for testing under extreme conditions.

The Temperature & Humidity Chamber allows researchers to replicate nearly any possible outdoor climate so that they can test air conditioner unit performance in a wide range of various conditions. This severe climate testing assures us that LG air conditioners can withstand any conditions and can also continue to provide complete comfort no matter what the circumstances.

Compression Chamber

Efficiency and durability are measured in the Compression Chamber.

An air conditioner compressor is as important as an engine is to a car. Compressors are tested in the Compression Chamber to determine the most effective materials and construction for LG Multi V compressors. LG has over 50 years experience in developing motors and this expertise is constantly being improved through Compression Chamber testing to ensure that the core technology in LG air conditioners continues to provide cool air while utilizing less electricity.

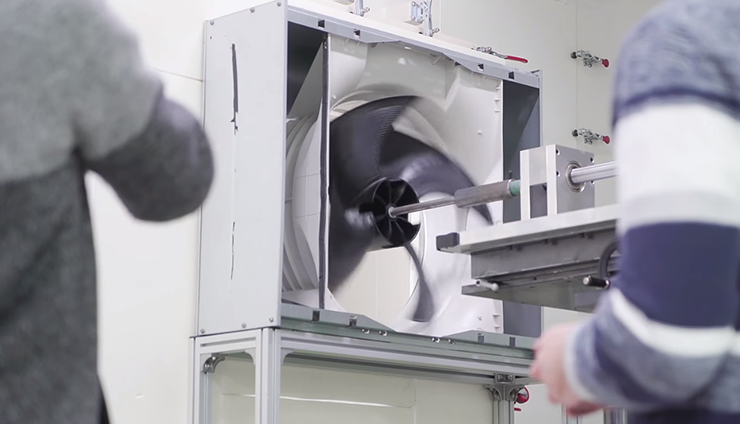

Fan Chamber

Fans are tested for noise and efficiency.

The Fan Chamber is where LG air conditioner fan efficiency is tested. LG researchers use biomimicry to develop quieter and more efficient fans. These fans use technology based on humpback whale fins and the surface of clam shells to achieve maximum efficiency.

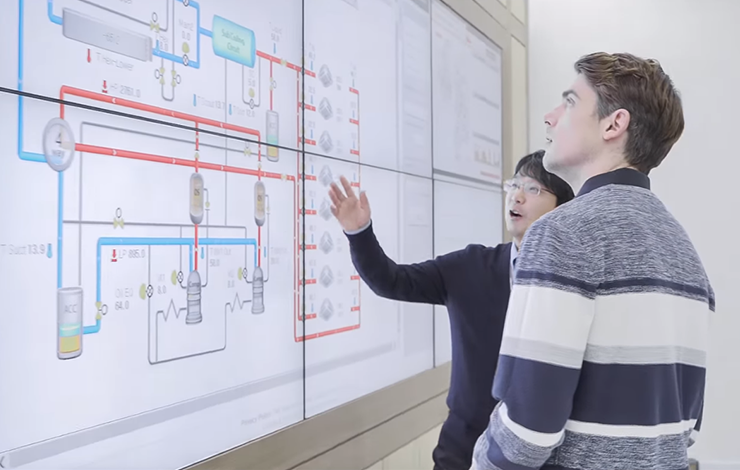

System Control

The fully integrated LG Air Solution Control Room

System Control hosts a fully integrated control room where system control solutions and smart control solutions are developed and monitored. LG researchers optimize control solutions using big data and AI technology to create more convenient and energy efficient solutions.

Field Testing

Real-time testing is done to ensure product quality.

Up on the Field Testing Deck, LG Air Solution has installed a wide range of outdoor units to test performance in a real, outdoor environment. The units installed here are run different increments and researched monitor their performance and durability over time to deliver the most effective air conditioners. Seeing the products run in real-time, you can see how reliable LG air conditioners truly are.

After a day at the LG Air Solution R&D Lab we now have a better understanding why LG is a market leader in efficient and convenient air conditioners. What can we expect from LG Air Solution in the future? From the looks of things, there is much more to come!